Application Methods and Techniques

Food coloring wood stain – Right, so you’ve got your food colouring ready to transform some humble wood. Let’s get down to the nitty-gritty of actually applying the stuff. This isn’t rocket science, but a bit of technique goes a long way to achieving a truly smashing finish.

The vibrant hues achievable with food coloring wood stain offer a captivating artistry, transforming ordinary wood into breathtaking masterpieces. Imagine achieving a particularly striking crimson, reminiscent of a hummingbird’s dazzling plumage – a color easily replicated using the intense pigment found in hummingbird red food coloring. This intense shade, when carefully diluted, adds a unique depth and brilliance to your food coloring wood stain projects, resulting in truly exceptional finishes.

The application method you choose will significantly impact the final look and feel of your stained wood. Factors like the type of wood, the desired colour intensity, and the overall aesthetic you’re aiming for all play a part in selecting the best approach. We’ll cover the most common methods and their respective pros and cons, so you can pick the perfect technique for your project.

Surface Preparation

Before you even think about wielding a brush, prepping your wood is absolutely crucial. This ensures a smooth, even application and prevents blotchiness. A poorly prepped surface is a recipe for disaster, trust me.

- Sand the wood to a smooth finish using progressively finer grits of sandpaper. This removes any imperfections and allows for better colour penetration.

- Clean the wood thoroughly to remove any dust or debris. A tack cloth is your best mate here.

- For particularly porous woods, consider applying a wood conditioner to ensure even stain absorption. This prevents blotchy areas where the stain soaks in unevenly.

Application Methods Comparison

Now for the main event: applying the food colouring. Each method has its quirks, so let’s weigh up the options.

| Method | Advantages | Disadvantages |

|---|---|---|

| Brushing | Good control, suitable for detailed work, relatively inexpensive. | Can leave brush strokes, requires more time and effort for large surfaces, potentially less even colour distribution than spraying. |

| Spraying | Fast and efficient for large surfaces, generally provides a more even finish. | Requires specialist equipment (spray gun and compressor), can be messy if not done carefully, potentially more expensive. |

| Dipping | Simple and effective for small items, allows for complete saturation. | Only suitable for small pieces, can be messy, may not be suitable for all wood types. |

Step-by-Step Application Guide (Brushing Method)

This guide uses the brushing method as an example; adapt as needed for other techniques.

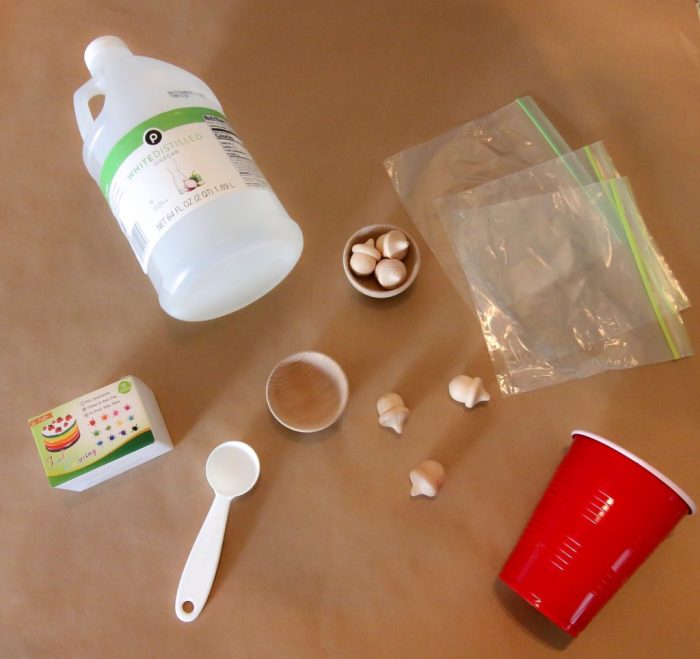

- Prepare your food colouring solution. Remember to test it on a scrap piece of wood first to check the colour.

- Using a clean, soft-bristled brush, apply a thin, even coat of the stain to the wood, working in the direction of the grain.

- Allow the stain to penetrate for a few minutes before wiping away any excess with a clean cloth. This prevents pooling and ensures an even colour.

- Let the wood dry completely. Drying time varies depending on the wood type, humidity, and the thickness of the application. Allow at least several hours, potentially overnight.

- Apply additional coats if necessary to achieve the desired colour depth. Allow each coat to dry completely before applying the next.

Creating Custom Wood Stains

Fancy a unique hue? Mixing your own food colouring stain is a doddle. Experimentation is key, but here’s a basic approach.

Remember, the ratios are a starting point; adjust to your liking. Always test on scrap wood first!

Example: For a dusky rose, try a mix of 2 parts red, 1 part pink, and a tiny dash of brown food colouring. Start with a small amount and gradually add more until you reach your desired shade. Thoroughly mix the solution before applying to your wood.

Remember to always wear appropriate safety gear, such as gloves and eye protection, when working with food colouring and wood stains.

Sealing and Finishing Techniques: Food Coloring Wood Stain

Right, so you’ve got your wood stained a vibrant hue using food colouring – top marks for creativity! But now, the crucial bit: protecting that masterpiece. Leaving your food-coloured wood unprotected is a recipe for disaster; the colour will leach, fade, and generally look a bit, well, rubbish. Sealing is absolutely essential to preserve your hard work and ensure longevity.Sealing methods for food-coloured wood require careful consideration due to the nature of the stain.

Unlike traditional wood stains, food colouring isn’t designed for this purpose and lacks inherent waterproofing. Therefore, a robust sealant is key to preventing colour migration and maintaining the vibrancy of your project.

Sealant Options and Their Suitability, Food coloring wood stain

Choosing the right sealant depends on the intended use of the finished piece. Several options exist, each with its own set of pros and cons. We’ll break down the most common choices, focusing on their durability, water resistance, and – importantly – their suitability for food contact.

| Sealant Type | Advantages | Disadvantages | Suitability for Food Contact |

|---|---|---|---|

| Polyurethane | Excellent durability, good water resistance, forms a hard, protective layer. Available in various finishes (gloss, satin, matte). | Can yellow over time, especially with UV exposure. Requires careful application to avoid bubbles and runs. Longer drying time. | Generally suitable if using a food-safe polyurethane, clearly labelled as such. Always check the manufacturer’s specifications. |

| Shellac | Creates a beautiful, warm finish, relatively easy to apply, fast drying time. Good for delicate projects. | Less durable than polyurethane, more susceptible to water damage, requires multiple coats for adequate protection. Can be more expensive. | Suitable for food contact when using a food-safe shellac, again, check the label meticulously. |

| Varnish | Offers good protection and a range of finishes, relatively easy to apply. Some varnishes are more durable than others. | Can be susceptible to scratches and chipping depending on the type. Drying time varies depending on the formulation. | Food-safe varnishes are available, but always verify this before applying to surfaces that will come into contact with food. |

Remember, always test your chosen sealant on a scrap piece of wood first to ensure compatibility with your food colouring and desired finish. This prevents any nasty surprises on your final project. Always follow the manufacturer’s instructions carefully for best results. And finally, if you’re unsure about the food safety of any sealant, err on the side of caution and choose an alternative.

Expert Answers

Can I use food coloring on all types of wood?

While many woods work, porous woods absorb color better. Hardwoods might require multiple coats.

How long does food coloring stain last?

It’s less durable than commercial stains and fades faster. Proper sealing is essential.

Is food coloring wood stain toxic?

Generally non-toxic when dry and sealed properly, but avoid food contact unless using food-safe sealants.

What’s the best sealant for food-contact surfaces?

Use food-safe polyurethane or varnish specifically designed for food contact surfaces.